Famous Brand Engineering Machinery Xz200 Horizontal Directional Drilling Rig

Product Description

It's applicable for pipeline construction about Municipal Construction (Electric, Communication, Water Supply) and Natural Gas,Oil Delivery.

| escription | Unit | Parameter value | |

| Engine | |||

| Manufacturers | Cummins | ||

| China III | Model | QSB5.9-C150 | |

| Rated Power | kW /(r/min) | 113 / 2200 | |

| China II | Model | 6BTAA5.9-C150 | |

| Rated Power | kW /(r/min) | 112/ 2200 | |

| EU Stage IIIA | Model | QSB4.5-C160 | |

| Rated Power | kW /(r/min) | 119/2200 | |

Thrust-Pull | Type | Pinion and rack drive | |

| Max thrust-pull force | kN | 225/225 | |

| Max thrust-pull speed | m/min | 26 | |

Rotation | Type | two motor | |

| Torque | N·m | 6350 | |

| Max spindle speed | r/min | 160 | |

| Loader Crance | / | / | |

| Max inclination angle | ° | 22 | |

| Pipe | Diameter × Length | mm×mm | Φ73×3000 |

Mud pump | Max Flow rate | L/min | 250 |

| Max pressure | MPa | 8 | |

| Weight | kg | 8500 | |

| Dimention | mm | 5900x2020x2400 | |

| Optional | 1. Cab 2. Air-condition 3. Full-automatic pipeloader 4. Single automatic anchor 5. Dual automatic anchor 6. Mud antifreeze 7. Automatic thread oil daub 8. Piston pump hydraulic system 9. Semi-automatic pipeloader 10. Mud cleaning | ||

Product Pictures

Directional boring, also referred to as horizontal directional drilling (HDD), is a minimal impact trenchless method of installing underground utilities such as pipe, conduit, or cables in a relatively shallow arc or radius along a prescribed underground path using a surface-launched drilling rig. Directional Boring/HDD offers significant environmental advantages over traditional cut and cover pipeline/utility installations. The technique is routinely used when conventional trenching or excavating is not practical or when minimal surface disturbance is required. Although often used interchangeably, the terms directional boring and horizontal directional drilling are distinct in that they convey a different sense of scale. The term "Directional Boring" or "Bore" is generally reserved for mini/small sized drilling rigs, small diameter bores, and crossing lengths in terms of hundreds of feet. Generally, the term Horizontal Directional Drilling (HDD) is intended to describe large/maxi sized drilling rigs, large diameter bores, and crossing lengths in terms of thousands of feet. Directional boring and HDD are similar in some respects to directional drilling associated with the oil industry, however, an equal comparison cannot be drawn as the procedures serve markedly different functions. Directional Boring/HDD can be utilized with various pipe materials such as PVC, polyethylene, polypropylene, ductile iron, and steel provided that the pipe's properties (wall thickness and material strength) enable it to be both installed and operated (if applicable) under acceptable stress limits. Directional Boring/HDD is generally accomplished in three principal phases. First, a small diameter pilot hole is drilled along a directional path from one surface point to another. Next, the bore created during pilot hole drilling is enlarged to a diameter that will facilitate installation of the desired pipeline. Lastly, the pipeline is pulled into the enlarged hole, thus creating a continuous segment of pipe underground exposed only at the two initial endpoints. Directional Boring/HDD can be utilized to cross any number of surface obstacles including roadways, railroads, wetlands, and water bodies of varying sizes/depths. The process is suitable for a variety of soil conditions including clay, silt, sand, and rock. Problematic soil conditions include large grain content in the form of coarse gravel, cobbles, and boulders. Other subsurface conditions which can impact the feasibility of Directional Boring/HDD include excessive rock strength and abrasivity, poor rock quality, and rock exhibiting karst features.

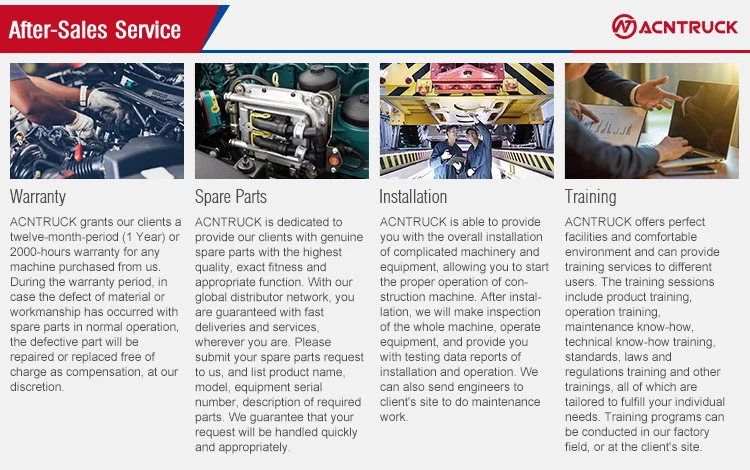

Compnay Information